Sebacic Acid & Esters

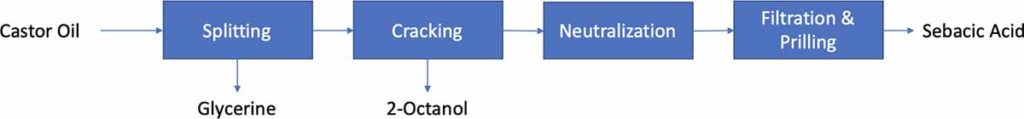

Process...

Castor oil is split into its fatty acids and glycerine. The castor oil fatty acids are cracked using an alkali fusion process which is carried out at elevated temperatures. The cracking reaction yields disodium sebacate along with 2- octanol. The disodium sebacate is further neutralized and purified to produce sebacic acid.

Grades of Sebacic Acid:

- Standard grade: Granules or Powder.

- Refined grade: Granules or Powder

Applications of Sebacic acid and it’s derivatives:

- Polyamides: Nylons 6,10; 10,10; 10,T; 4,10 are produced using sebacic acid as a monomer. These are used in a wide variety of applications ranging from piping to automotive.

- Polyesters: Used in adhesive applications.

- Polyurethanes: Used in coating and adhesive applications.

- Plasticizers: Sebacate esters are used in low temperature plasticizer applications.

- Lubricants and Grease: Salts and esters of sebacic acid are used in automotive and metal working lubricants.

- Corrosion inhibitors: Salts of sebacic acid are used in corrosion inhibitors in automotive, aircraft and truck applications.

- Cosmetics: Esters of sebacic acid are used in cosmetic applications such as creams and emollients.

Sebacic Esters:

- Dimethyl sebacate

- Dibutyl sebacate

- Dicapryl sebacate

- Dioctyl sebacate

- Diisopropyl sebacate

Sebacate esters are typically used as synthetic intermediates, low temperature plasticizers, emollients, plastic additives and coating additives.

Octanol Applications:

- Solvent for coatings and adhesives.

- Esters for plasticizer and cosmetic applications.

- Rare earth mineral extraction solvent.

- Tobacco and Banana Suckericide.

- Defoamer in oilfield chemicals.

- Flavor and Fragrance.

Producers:

- Arkema (Casda)

- Hengshui Jinghua

- Jayant Agro-Organics Ltd.

- Wilmar