Manufacturing of Castor Oil

Process...

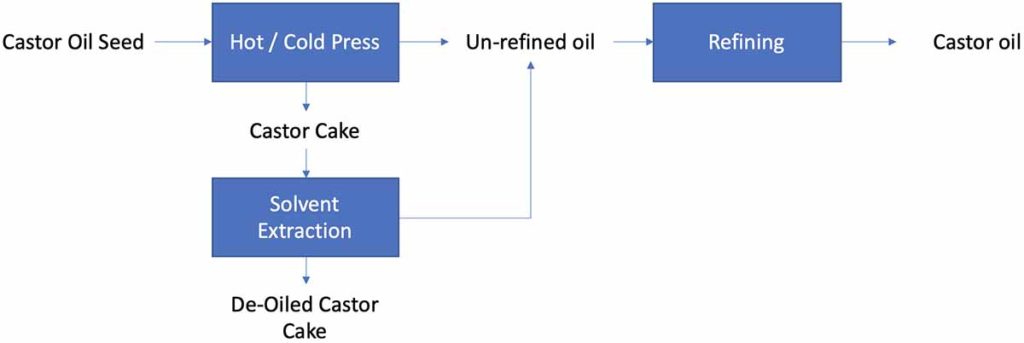

Castor oil is extracted either by hot pressing or cold pressing to extract the initial oil content. The remaining oil content is extracted using a solvent extraction technique typically involving n-hexane as the solvent. The oil is refined and packed for dispatch in liquid form. The leftover extracted solid is known as de-oiled cake.

Castor Oil Characteristics

Chemical Composition

Castor oil is a triglyceride of fatty acids. It is unique in that it contains 85-90% of Ricinoleic Acid (12-hydroxyoctadec-9-enoic acid), a rare source of 18 carbon hydroxylated fatty acid with 1 double bond.

Grades of Castor Oil:

- Commercial

- First Special (FSG)

- Pale Pressed (PP)

- Pharmaceutical

Castor Oil Applications:

- Engineering Plastics: Used to make monomers for nylon 6,10; nylon 10,10; nylon 11.

- Surfactants: Surfactants made from castor oil are used in textiles, agrochemical formulations, pharmaceuticals and paints.

- Cosmetics: Lipsticks, glosses, nail polish lacquers, eye mascara, rouge and skin creams.

- Pharmaceutical: Excipients, laxatives.

- Coatings: Used in polyurethane systems and alkyd based resins.

- Adhesives: Used in polyurethane adhesives, rubber-based adhesives and binders.

- Electrical: Used as a dielectric liquid impregnant for capacitors.

De-Oiled Castor Meal Applications.

- Fertilizer: Used as an organic fertilizer due to its excellent blend of N:P:K (4:1:1) with micronutrients such as Zinc, Manganese and Copper. This nourishes the soil over longer periods of time. Used for tea, coffee, sugarcane, potato, tobacco, vegetables, fruits and pulses.

- Fuel: Used as a renewable fuel due to its comparable calorific value with coal.

Producers:

- Jayant Agro-Organics Ltd.

- Adani Wilmar

- N.K. Proteins Pvt. Ltd.

- Gokul Agro Resources Ltd.

- Gokul Agri International Ltd.

- Kandla Agro

- CastorGirnar Industries Pvt. Ltd.