Hydrogenated Castor Oil

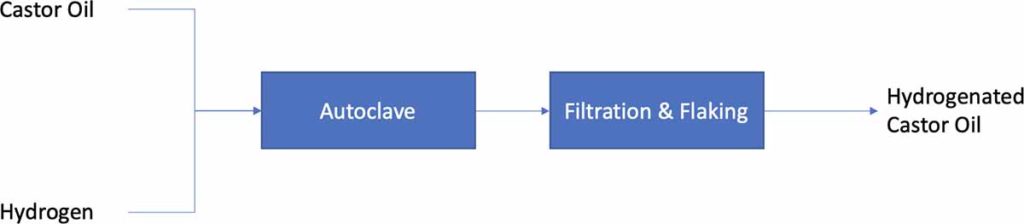

Process...

Castor oil and hydrogen gas are mixed in an autoclave along with a catalyst. High pressure and temperature are exerted onto this mixture to produce hydrogenated castor oil. This waxy substance is filtered and flaked to form finished hydrogenated castor oil flakes.

Grades of HCO:

- Flakes

- Powder

Applications of HCO:

- Lubricants: Multipurpose premium quality greases.

- Paper Coatings: Water-barrier e.g. bread paper, soap wrappers, etc.

- Processing Aid: Lubricant for PVC, PE processing.

- Polishes: Shoe, metal, furniture.

- Inks: Dispersing additives, resins and binders.

- Pencils & Crayons: To improve writing quality.

- Cosmetics: Creams, ointments, lipsticks, deodorant sticks.

- Electrical applications: Sealant.

- Adhesives: Hot melt, binders.

Producers:

- Jayant Agro-Organics Ltd.

- Royal Castor Products Pvt. Ltd.

- Adani Wilmar

- Vertellus

- Tianxing Biotechnology Co. Ltd.

- N.K. Proteins Pvt. Ltd.

- Gokul Agro Resources Ltd.

- Gokul Agri International Ltd.

- CastorGirnar Industries Pvt. Ltd.